Industry-specific mechanical engineering industry support for success.

Industry-specific mechanical engineering industry support for success.

Blog Article

Top Tips for Effective Electric System Troubleshooting

Repairing electric systems needs a methodical approach, based in a thorough understanding of electric concepts and safety and security methods. The nuances of efficient troubleshooting extend beyond simple technical expertise; recognizing just how to document searchings for and prioritize security can significantly affect end results.

Understand the Basics

Comprehending the fundamentals of electrical systems is essential for efficient troubleshooting, as a solid foundation allows professionals to diagnose and deal with problems extra efficiently. A thorough understanding of electrical concepts, such as voltage, existing, resistance, and power, is crucial in recognizing the origin of problems. Voltage is the electrical potential distinction that drives existing with a circuit, while resistance opposes the flow of existing, impacting the total capability of the system.

Experience with circuit components, consisting of resistors, capacitors, diodes, and switches, is also paramount. Each element plays an unique function in circuit behavior and can impact efficiency when malfunctioning. Additionally, comprehending series and parallel circuit configurations is vital, as these arrangements influence the distribution of voltage and existing within the system.

Professionals must be mindful of prospective hazards, such as shock and brief circuits, to execute safe troubleshooting methods. By mastering these foundational concepts, specialists enhance their capacity to carry out effective diagnostics and fixings, eventually leading to improved performance and dependability of electrical systems (electrical system troubleshooting).

Gather Necessary Tools

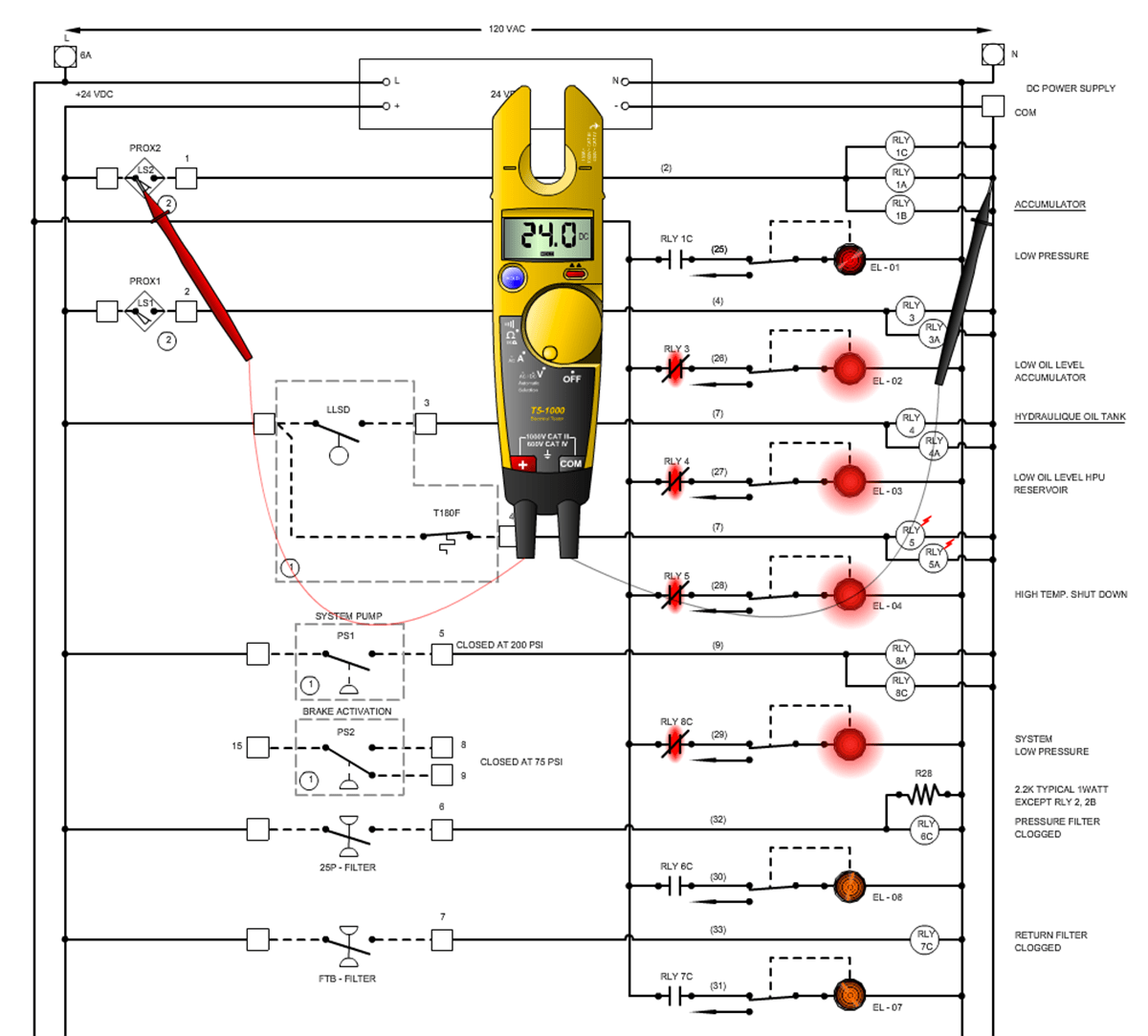

Efficient troubleshooting of electric systems calls for the ideal collection of devices to diagnose and fix concerns precisely. Essential devices include a multimeter, which gauges voltage, present, and resistance, allowing for precise analyses of electric parts.

Furthermore, insulated hand devices such as screwdrivers, pliers, and wire strippers are crucial for securely controling electric links. It is additionally advisable to have a circuit tester available to confirm the existence of voltage in outlets and cables. For more complicated systems, a thermal imaging camera can assist identify overheating components, indicating potential failings.

Follow an Organized Method

Having actually collected the appropriate devices, the following action in repairing electric systems is to adhere to a systematic strategy. A systematic strategy ensures that technicians can determine faults successfully and precisely, reducing downtime and preventing unnecessary repair work.

Begin by evaluating the system's schematic layouts and specs. Understanding the layout and functional parameters will supply context for identifying issues. Next off, separate the trouble location by using a process of removal. This involves checking each part methodically, starting from the source of power and functioning in the direction of the load.

Utilize testing tools, such as multimeters and oscilloscopes, to gather unbiased data about voltage, current, and resistance at various factors within the system. This empirical evidence will direct your troubleshooting efforts and aid to verify or eliminate possible blog here sources of failing.

In addition, think about ecological elements that might affect the system's efficiency, such as temperature changes or dampness ingress. A detailed inspection of circuitry, connections, and elements will make sure that all possibilities are accounted for.

File Your Findings

Complete paperwork is important in the repairing procedure of electric systems. Precise documents enhance the performance of identifying persisting concerns and assist in interaction among staff member. Each finding ought to be diligently noted, consisting of symptoms observed, tests performed, and the outcomes of those tests. electrical system troubleshooting. This method not just help in comprehending the source of the problem however additionally offers as a reference for future fixing initiatives.

In addition, preserving a log of parts replaced or fixings executed is indispensable. This info supports inventory monitoring and can assist evaluate the longevity and integrity of certain elements.

Ultimately, the documents process should be thorough yet succinct, making it possible for simple access and evaluation - electrical system troubleshooting. By prioritizing thorough paperwork, service technicians can create a valuable expertise base that not only help in present troubleshooting but likewise empowers future upkeep initiatives, therefore enhancing total system dependability

Prioritize Safety Actions

Acknowledging the integral risks linked with electrical systems is vital for ensuring security throughout troubleshooting. Electric shock, burns, and equipment damage are simply a few of the potential dangers that specialists encounter. Focusing on security procedures is not only a legal obligation you could check here however additionally a moral imperative that safeguards both the specialist and the surrounding setting.

Prior to beginning any type of troubleshooting job, technicians must put on appropriate personal protective devices (PPE), including insulated handwear covers, shatterproof glass, and flame-resistant garments. Making certain that the workspace is completely dry and totally free of clutter can dramatically decrease the danger of accidents. It is important to de-energize circuits before beginning any type of job, verifying that they are not live with the usage of a multimeter or voltage tester.

Developing clear interaction protocols with team members is likewise crucial; this makes sure that everybody is conscious of prospective risks and the condition of the electric system being serviced. Lastly, having an emergency response plan in position can confirm indispensable in the event of an occurrence. By focusing on pop over to this site safety and security procedures, service technicians can successfully minimize dangers and cultivate a more secure office.

Verdict

Effective electrical system troubleshooting counts on a comprehensive understanding of basic concepts and a methodical strategy. By gathering vital devices, adhering to organized examination techniques, and diligently recording findings, the repairing procedure becomes more reliable and trustworthy. Prioritizing safety and security actions makes sure the well-being of people entailed and the stability of the electric system. Executing these approaches will enhance the repairing experience, resulting in quicker resolutions and boosted operational effectiveness in electric systems.

Report this page